Aritco Homelift CEO Visit HD Homelift Showroom PH

July 10, 2025

HD Homelift Solutions First Mooncake Festival: Celebrating Innovation, Culture, and Connection

October 27, 2025Traction Home Elevator vs Screw and Nut Home Elevator: Why the Smarter Choice Might Surprise You

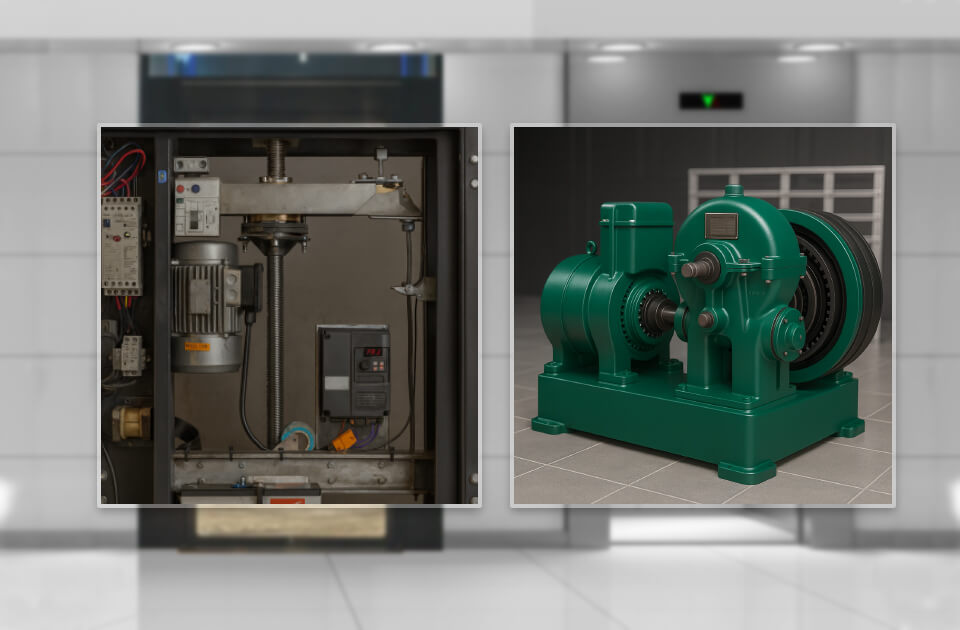

When homeowners begin exploring lift options, the traction home elevator often appears as a tried-and-true solution. Using rope-and-counterweight technology, it’s been a staple in many multi-level homes for years. However, another option the screw-and-nut home elevator is steadily gaining attention for its efficiency, space-saving design, and ease of ownership. No machine room is needed in a residential elevator, unlike systems used in a factory or station. As a leading elevator supplier company, we integrate advanced home lift solutions. Whether for strict quality control for passenger elevator, or even a choice of traction type home elevator, a screw and nut mechanism currently leads the market.

In this guide, we’ll look at how a traction home elevator works, weigh its pros and cons, and explore why a screw-and-nut home elevator might be the more practical, future-proof choice for your home.

Understanding Traction Home Elevator Technology

A traction home elevator uses steel ropes or belts connected to a counterweight, powered by an electric motor. As the motor turns a drive sheave, friction moves the ropes, lifting or lowering the cabin. This system, scaled down from commercial traction elevators, is adapted for residential use to provide smooth rides and handle moderate travel distances between floors. As elevator manufacturer release different types of elevators, their systems offer improved drive system, electrical, wire rope, elevator shaft, and control system fit for residential lift.

While dependable, traction home elevators come with certain installation and maintenance needs that may not suit every home especially those with limited space or older structures.

Key Features of a Traction Home Elevator

Smooth ride quality – comfortable travel between floors.

Reliable operation – proven technology adapted for homes.

Moderate travel height – works well for multi-level residences.

Requires a pit and adequate headroom – may require structural changes.

Higher maintenance needs – ropes and mechanical parts require periodic inspection and replacement.

Why a Screw-and-Nut Home Elevator Might Be the Better Choice

A screw-and-nut home elevator operates on a simple yet efficient principle: a large vertical screw shaft is rotated by a motor, and a nut attached to the cabin moves along the screw, raising or lowering the lift. This direct mechanical drive eliminates ropes, counterweights, and complex pulley systems. This professional elevator continuously improves the operator layout, which prevents outage and advances process of manufacture of the elevator company, resulting in high performance in the long run.

For homeowners especially those adding an automatic gearless elevator to an existing property, this design offers several compelling advantages over traction systems.

Advantages of a Screw-and-Nut Home Elevator

Pitless – No need for costly excavation or deep foundation work.

Minimal headroom requirements – Fits easily into spaces with low ceilings.

Highly energy efficient – Consumes lower wattage for reduced electricity costs.

Easy to troubleshoot – Fewer moving parts make repairs quicker and simpler.

Affordable maintenance – Reduced wear-and-tear means lower long-term expenses.